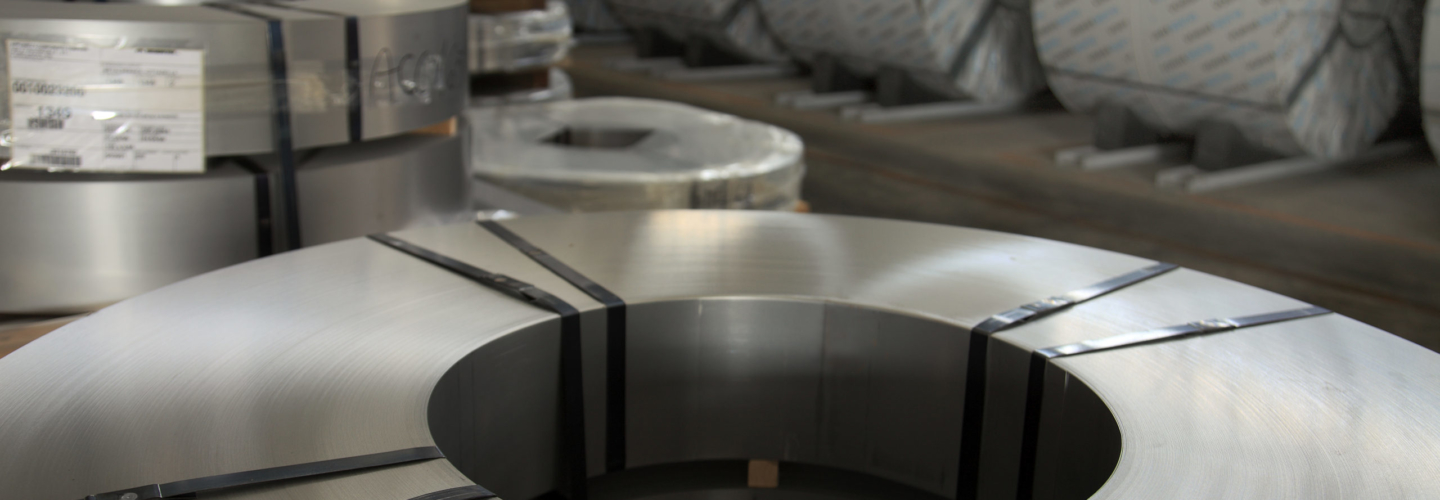

Isovac® Electrical Steel

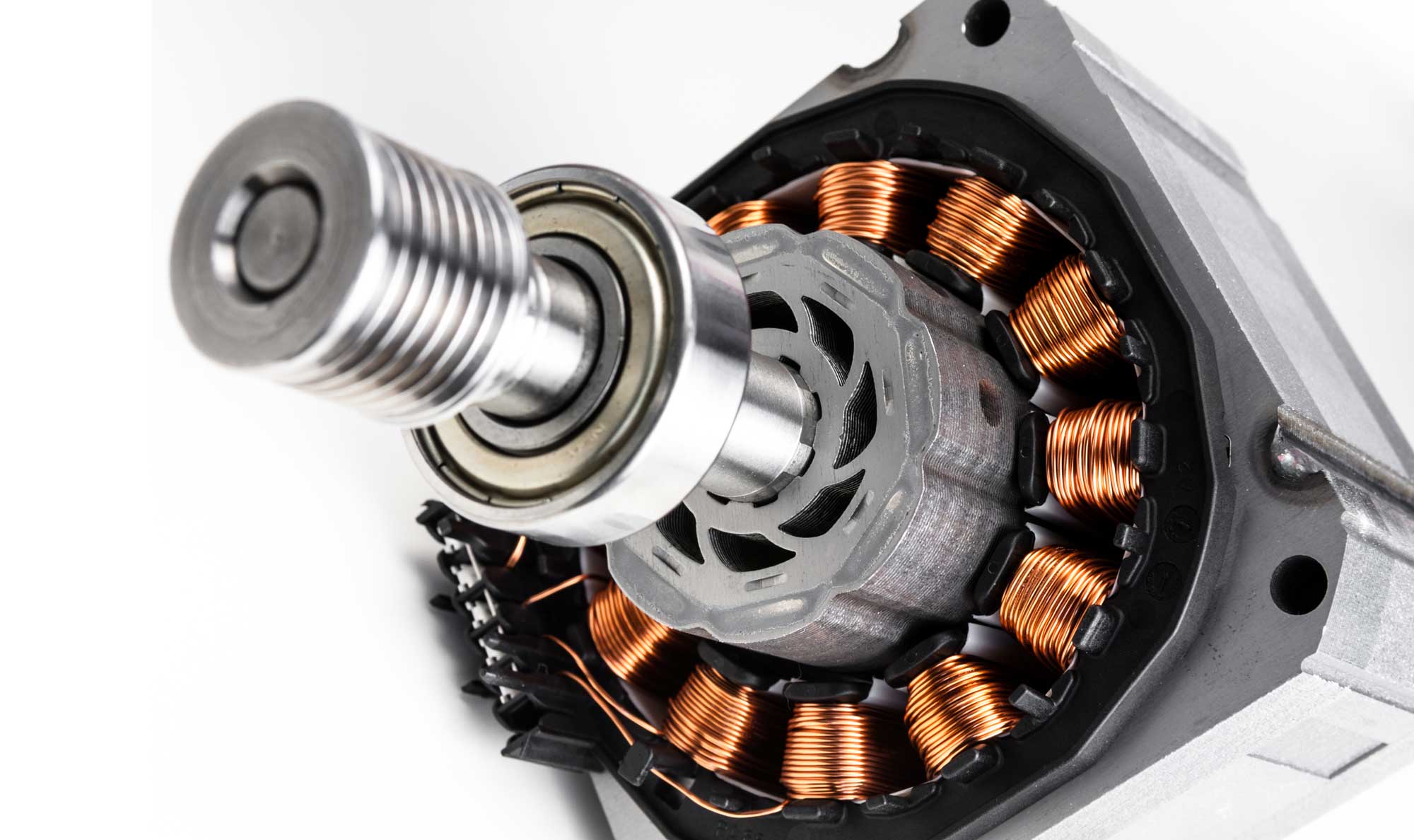

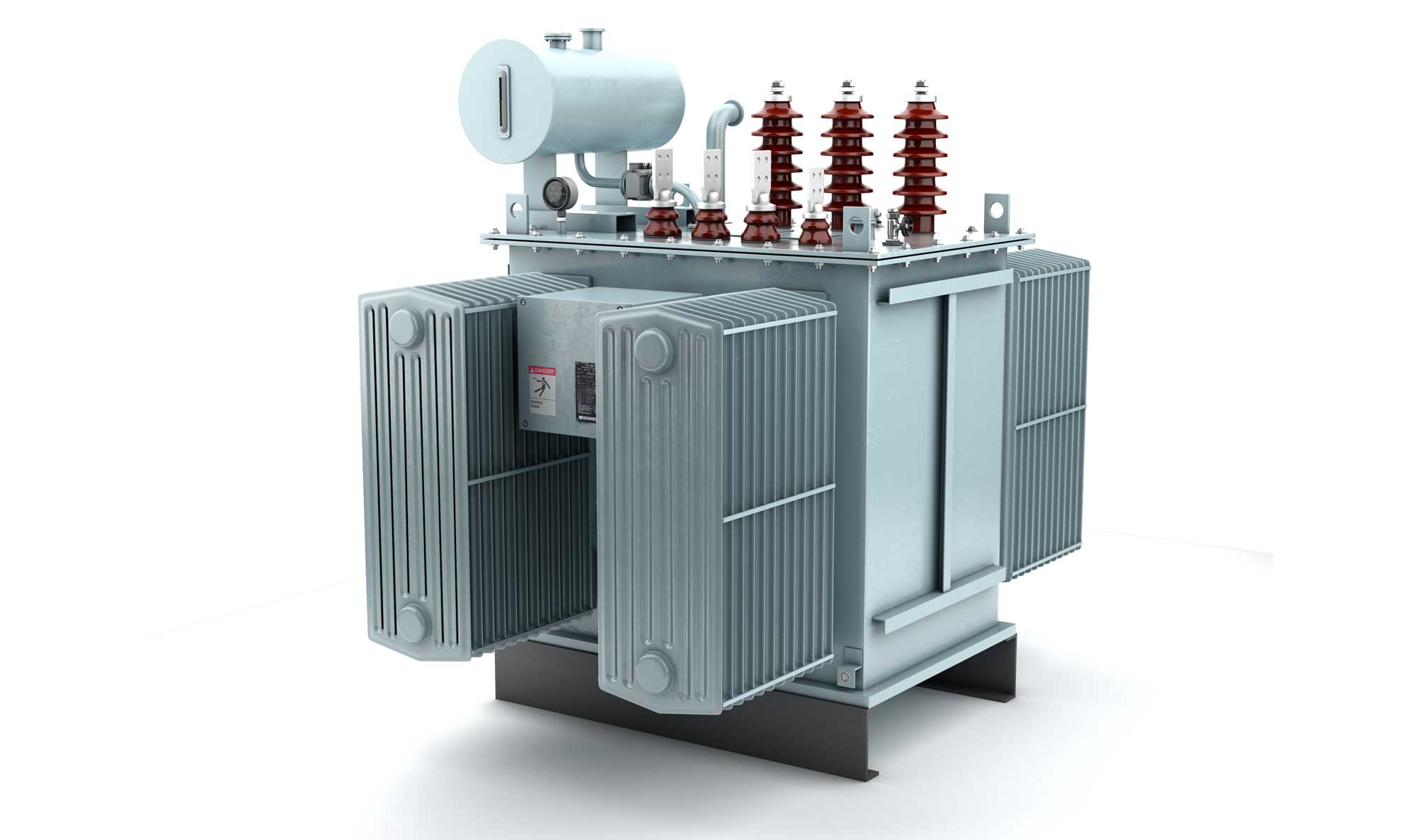

Isovac® is a brand name of voestalpine Stahl GmbH and stands for non-grain oriented electrical steel strip and sheet of the highest efficiency. In-depth material expertise, research and development in partnership with global leaders in the fields of electromobility and generator manufacturing and the use of state-of-the-art technologies make isovac® one of the highest-quality industrial solutions with respect to innovative materials, logistics, distribution and technical consulting.

isovac® standard products:

> isovac® in the fully processed condition EN 10106

> isovac® in semi-processed condition EN 10341

Isovac special products®:

> isovac® high-perm

> isovac® high-frequency

> isovac® high-conductivity

> isovac® high-strength

> isovac® high-efficiency

> isovac® NO (e-mobility; from 0.25 to 0.35 mm) (EN 10303)

Insulation coating types:

>C3 varnish: organic varnish for significant improvement of stampability

>C5 varnish: various products with high insulation resistance and the appropriate coating thickness

These coatings are highly suitable for welding and stamping.

See https://www.voestalpine.com/isovac/en for further information.

Cold rolled non-grain oriented electrical steel in fully processed condition

(pursuant to EN10106)

The magnetic properties are fully developed in as-delivered condition, and it is no longer necessary to anneal the material after punching.

Reference standard EN 10106 pertains to sheets and strips of cold-rolled non-grain oriented electrical steel in fully processed condition with a nominal thickness of 0.35 mm, 0.50 mm, 0.65 mm and 1.00 mm. The standard features general requirements for magnetic and geometric properties as well as tolerances, technological properties and test conditions.

Cold rolled electrical steel of non-alloyed and alloyed steels in semi-processed condition

(pursuant to EN10341)

Semi-processed electrical steel must be annealed at the customer in order to achieve specific electromagnetic properties.

Reference standard EN 10341 pertains to sheets and strips of unalloyed and alloyed non-grain oriented electrical steel in semi-processed condition with a nominal thickness of 0.50 mm, 0.65 mm and 1.00 mm. The standard features general requirements for magnetic and geometric properties as well as tolerances, technological properties and test conditions.